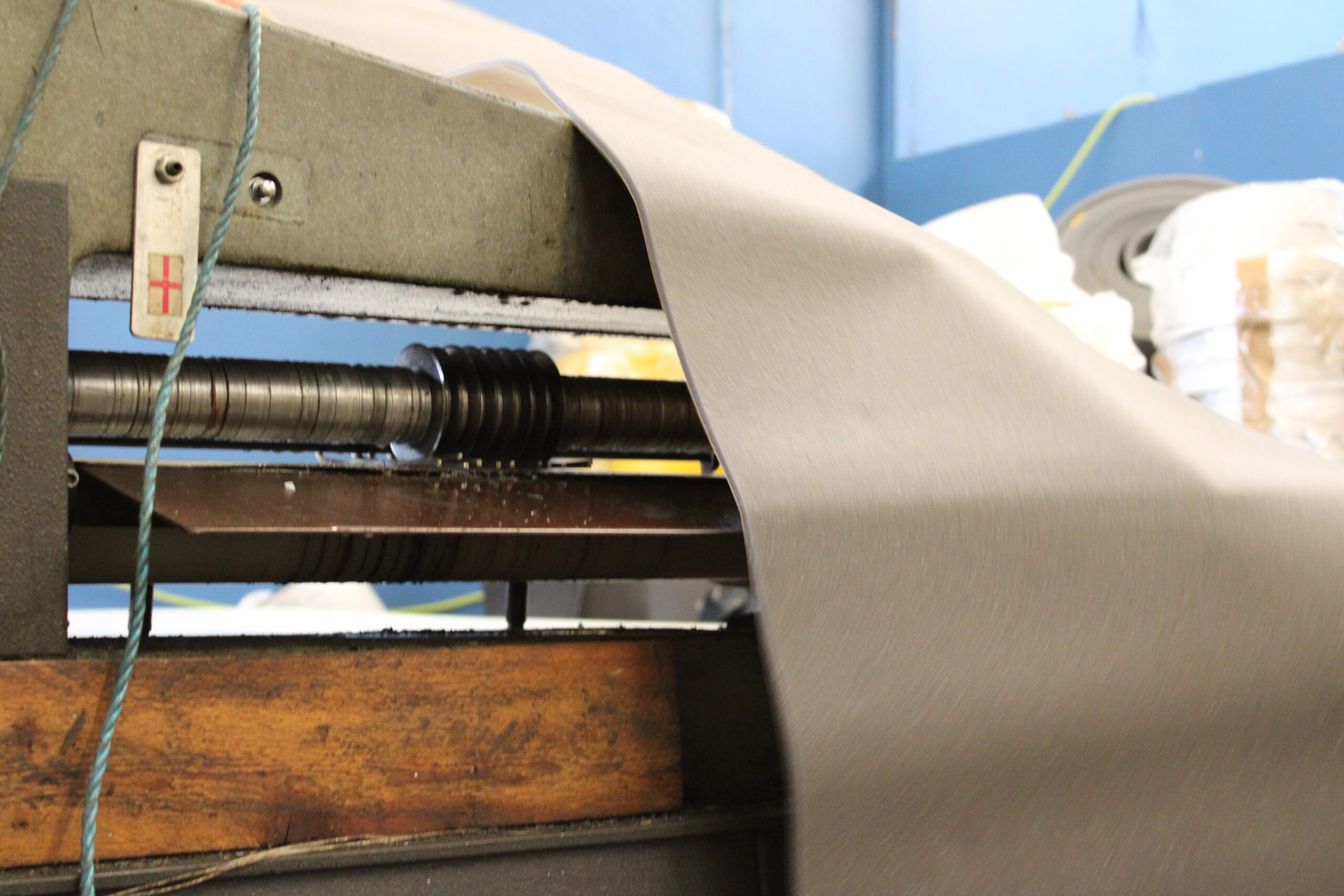

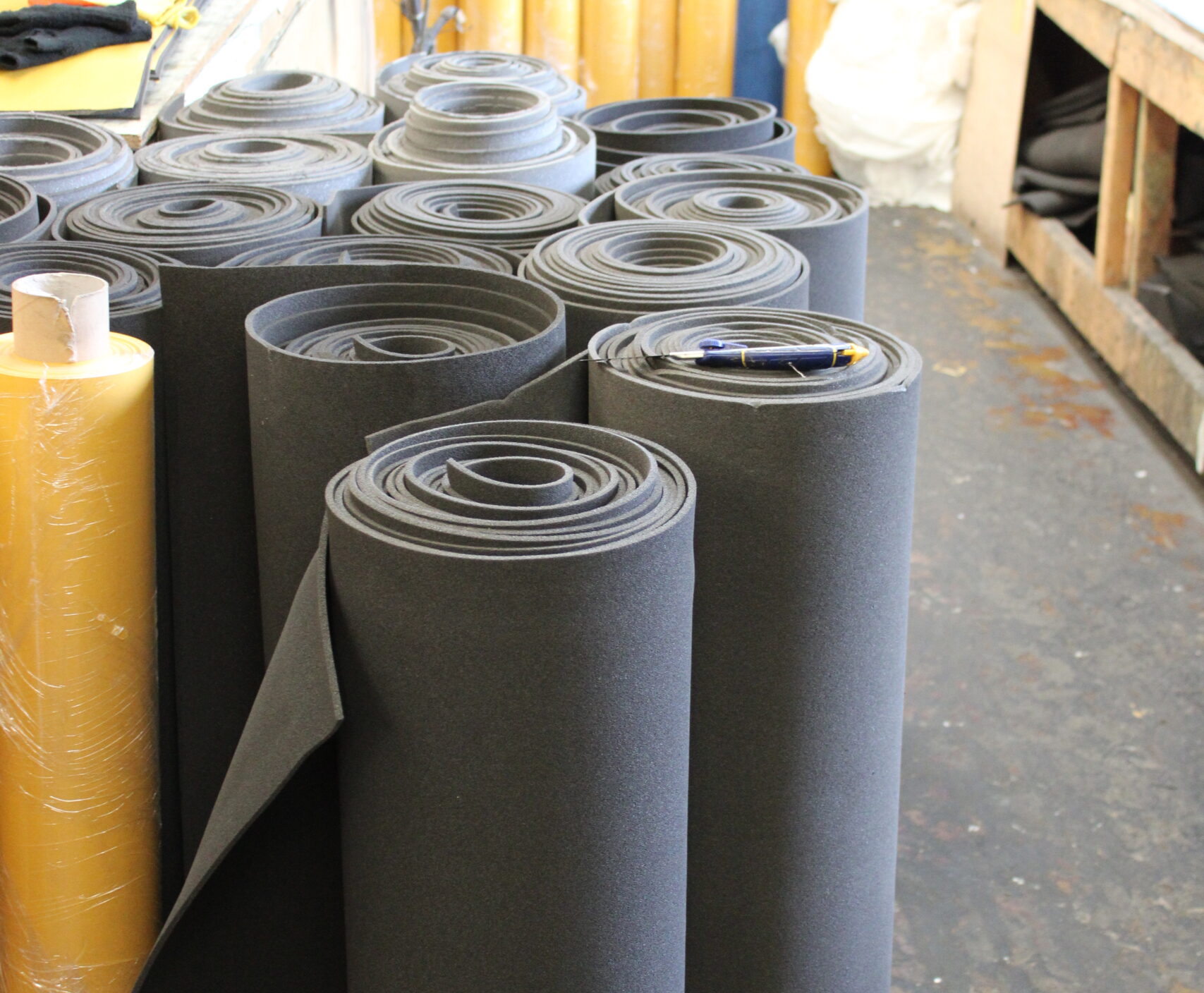

Foam is a versatile and ubiquitous material that can be found in a wide range of products, from furniture and bedding to packaging materials and athletic equipment. As a foam manufacturer, keeping up with the latest innovations in foam manufacturing is critical to staying competitive and meeting customer demands. In this article, we’ll explore some […]

Rubber, Plastic & Foam

UK Manufacturers

GKA Rubber & Plastics manufacturer a range of products spanning from gasket, seals and more.